-

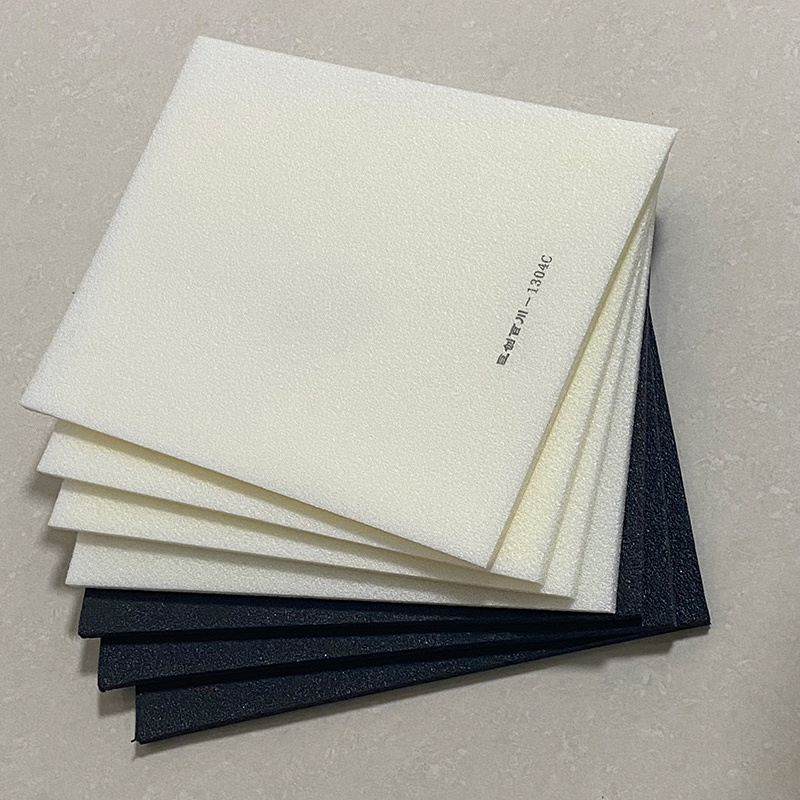

Foam materialMain business for high density polyethylene (XPE) new environmental protection coil research and development, production and sales.

-

Foam applicationThe products are widely used in high-end car interiors, car mats, children's climbing mats, yoga mats, wrestling mats, judo mats, building insulation, etc., with good insulation Heat insulation, waterproof and moisture-proof, sound insulation and shock absorption.

-

StrengthThe company covers an area of 13339.87 ㎡, now has 2 environmental protection New material (XPE) production line, supporting the construction of internal mixer, extrusion granulator, calender, mixer, pelletizer and other main and auxiliary equipment more than 10 sets, with an annual output of 8000 tons of environmentally friendly new materials (XPE).

-

BlogFollow us and learn more about industry dynamics. Tailored to belong to your foam products solutions.

-

About usFounded in March 2022, the company's main business is the research and development, production and sales of high-density polyethylene (XPE) new environmentally friendly coils, and is committed to providing a full range of customized products according to the different needs of customers.

Production process and application of IXPE

Production process and application of IXPE

The production process of IXPE includes raw material preparation, extrusion, foaming, calendering, cutting and other links. First of all, high-quality polyethylene resin is selected as the main raw material, and after mixing, heating and extrusion molding, IXPE foam sheet is formed. Subsequently, foaming treatment is carried out under specific conditions, so that the IXPE foam sheet expands and closes the cells, thereby improving its heat preservation, sound insulation, waterproof and other properties. Then, the IXPE foamed sheet was calendered and cut to make various specifications and shapes of finished products.

IXPE is widely used in various fields because of its excellent performance. In the construction field, IXPE is widely used in roof insulation, floor sound insulation, pipe insulation and other aspects; in the automotive field, IXPE is used in automotive interiors, sound insulation panels, door seals and other parts; in the packaging field, IXPE is used in electronic product packaging, food preservation, cold chain transportation and other aspects. Because IXPE has good flexibility, wear resistance and corrosion resistance, its application range is constantly expanding, and it will have a wider market prospect in the future.

If you are interested in our products, please leave your contact information and we will contact you as soon as possible. Thank you.